More and more these days the craft beer industry touts the environmental advantages of packaging its beverages in aluminum cans. And for good reason: aluminum, or aluminium as much of the world prefers, is lighter than glass and therefore requires less energy use for distribution, and the valuable element is among the most highly recycled materials in the world. Internationally, the aluminum can recycling rate is nearly 70 percent. Notoriously poor American recyclers, on the other hand, aren’t even achieving a 50 percent rate. According to the Container Recycling Institute, in the U.S. alone more than a trillion beer and soda cans have been trashed rather than recycled since their mainstream use began some five decades ago.

That’s a shame, because the carbon footprint for producing an aluminum can made from recycled aluminium is dramatically lower than that of a can sourced purely from mined bauxite, a process that’s energy intensive and results in significant land degradation. It’s especially regrettable when you consider that beer and other beverage cans are infinitely recyclable, meaning that unlike plastic for example, they can be recycled into new cans over and over without compromising the quality of the aluminium. What’s more, the process of producing new cans from recycled ones typically takes just 60 days.

Given how far below the 100 percent recovery rate the world is, consumers and industry (can producers, breweries, retailers, drinkers/recyclers) could certainly be doing better. Follow the steps below to increase the odds that your infinitely recyclable aluminum beer cans actually get recycled.

1

2

3

4

5

In closing, it’s important not to miss the point that the difference between something being “recyclable” and whether it actually gets recycled is a profound one. If packaging craft beer in aluminium cans is to be marketed as better for the environment, industry and consumers will need to work a little harder to make sure it happens.

Everyone who inhabits our planet – brewers, retailers, and drinkers alike – lives in a world with limited natural resources. There’s no middle ground here. “Sort of” sustainable or “more sustainable than another material” isn’t actually meaningful. Nor is “aspiring” to achieve a better recycling rate. A worldwide recovery rate of 90 percent or better for an infinitely recyclable material such as aluminum is sustainable. Anything less is just marketing. ![]()

![]()

Note (1): If you live in one of the 10 states with a bottle deposit law (California, Connecticut, Hawaii, Iowa, Maine, Massachusetts, Michigan, New York, Oregon, and Vermont) and plan to redeem your can, leave the label on.

Note (2): All of the above tips apply to glass bottles as well, which are also infinitely recyclable. Unfortunately, the likelihood of glass actually being “recycled” back into glass largely depends on whether glass recycling facilities exist in the part of the world you live in. In many regions, they do not.

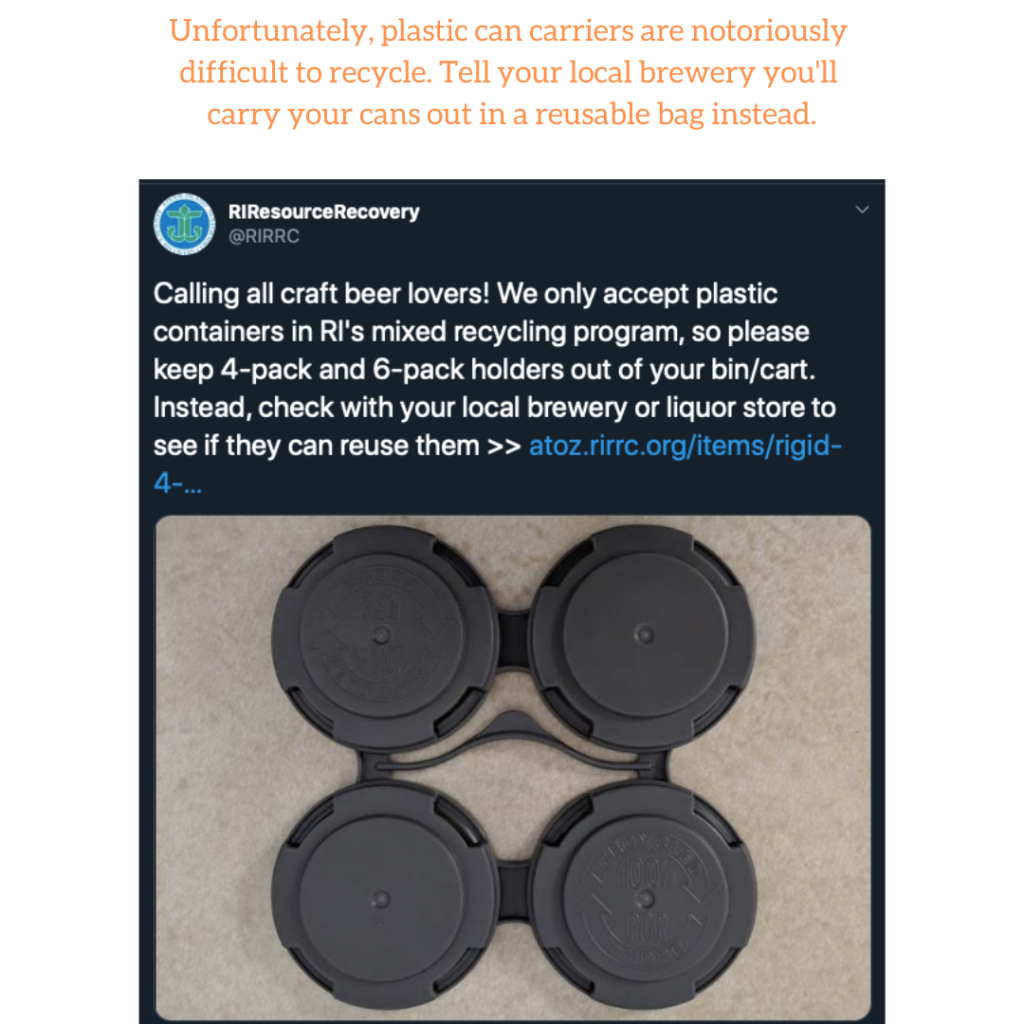

Craft Brewers Ditching Plastic Can Carriers for Eco-Conscious Options

I love the steps to recycling detailed in this article. It’s important to remove any shrink sleeve labels and to not crush the can to ensure proper recycling.

Note that the aluminum beverage can recycling rate in the U.S. was actually at 50% in 2018 (https://www.aluminum.org/sites/default/files/KPI%20Report%202019.pdf), and the can industry is committed to increasing that number.

Thanks for spreading the word about how to recycle cans and why it’s important!

Hi Scott: Thanks for the support, hopefully we can raise that recycling rate considerably in the very near future. An “infinitely recyclable” material is only sustainable if it’s actually getting recycled. We all need to work harder at making that happen: producers need to take ownership of the problem through extended producer responsibility (EPR) efforts that support deposit/redemption programs, and work with beverage makers and retailers to ensure that they too are embracing EPR in the form of collections efforts. It can’t all just be left to the consumer and the taxpayer funded municipal curbside recycling programs. Cheers to sustainable beers, and to proper stewardship of the recyclable vessels they are packaged in.

Just a fabulous article about an issue that has only recently come to light, that of the crowler cans that have labels that must be peeled off before they can be recycled. Also those 4-pac carrier things that I thought were MORE recyclable turn out to be LESS recyclable. Then again, what’s the point if the recyclers trash most of what we’re giving them?? This country needs a concerted effort to create a program that energizes our recycling industry so we have less of this kind of thing going on. Beer Drinkers Unite!

Hi there – this is super helpful. What happens if I dont peel off the plastic sticker on the can? Will it not be recycled? where can i get a definite answer for this? Many thanks in advance!

Hey Deepika: It will probably still get recycled, for now. But as craft beer has grown, and more and more vinyl stick-on and shrink-wrap labels are bing used, the aluminum recycling industry has started to become concerned about the level of contamination and other issues. Luckily, some breweries are starting to use tear-off labels so consumers will know to take them off before pitching cans into recycling bins. Here’s an excerpt from a good summary of the issue, written by beer expert Kate Bernot: “They still take these cans for now, but the labels can cause issues with equipment wear-and-tear at recycling facilities. I’ve heard some facilities say that they can increase fire risk. Some say the labels reduce efficiency by introducing non-aluminum material into their processes,” he says. “And others say the plastic labels cause emissions spikes when the cans with them are melted down.” If you want to read the full story here’s the link: https://thetakeout.com/are-shrink-wrapped-beer-cans-recyclable-1832063063

If I crush my beer cans can a school or any charitable organisation benefit from this

Cheers T D

Hey Terry: It depends on whether your cans are ultimately going to a redemption center (where they need to be scared) or a material recovery facility (MRF) where they will need to be sorted. If the charitable organisation is just going to sell the aluminum (by weight) straight to a scrap metal recycling processor it probably doesn’t matter. Might be best to ask the charity what they know about the process. Cheers

It’s great that aluminum cans are ‘infinitely recyclable’. But, that only makes a difference if that recycled material is actually used right? I notice that the microbrews that I have been drinking are not using recycled aluminum. (Or does recycled aluminum simply not advertise that is is derived from recycled material?). Are there any breweries that you know of that are actually using recycled material? I’d love to support them!! Thanks!

Hi Julie: Great question, and one that more consumers should be asking about all materials used to produce products and packaging. Short answer: all aluminum beverage cans are manufactured with recycled content despite no labeling to that effect (like you sometimes see on cardboard or paper products). Unfortunately, only two thirds of the material used to produce new cans actually comes from recycled content, the rest is virgin material, mined bauxite – one of the most energy intensive and environmentally harmful processes on earth. Bottom line: while everyone should recycle their cans (current rate here in the U.S. is a woeful 49%), know that single-use is NOT sustainable. Hence the often cited but seldom understood waste hierarchy of REDUCE, Reuse, then recycle.