Planet Earth — Single-use plastic packaging increasingly faces scrutiny for its negative environmental and human health impacts and is the focus of various laws and regulations aimed at banning, reducing, or better recycling it. A wave of bills are currently under consideration by federal and state legislatures. Given such a landscape, forward-thinking and eco-conscious businesses would be wise to look beyond just cost and convenience when making packaging decisions.

Short of forgoing can carrier packaging all together, which isn’t as crazy as it may sound, there is currently no perfect solution on the market. Fortunately, alternatives to single-use plastic have emerged and continue to improve. In most cases, their cost is now competitive with those of the beverage industry’s largest manufacturers. This article’s goal is to help craft beverage producers find the right solution for their specific goals and needs by highlighting some of the advantages and disadvantages of various options.

Considerations include (1) the material the packaging is made from, (2) the origin of that material, (3) the likelihood the packaging will be reused, composted or recycled, (4) the risk the packaging poses to nature (water, soil, air quality, wildlife) if it leaks into the environment, (5) pollution associated with the packaging’s unintended but likely end-of-life circumstance (landfill or incineration), (6) the packaging’s overall carbon footprint (which can be difficult to assess), and (7) consumer sentiment regarding the packaging’s convenience/performance versus its environmental impact.

Originator of the plastic 6-pack ring, long reviled by environmentalists, Hi-Cone’s can packaging was reported to have killed countless seabirds and marine mammals annually until the EPA finally mandated in 1994 that it be made from a degradable material. The change to photodegradable plastic decreased entanglement risk to wildlife because 6-pack rings now break down when exposed to sunlight (though the process varies depending on conditions, especially the amount of sunlight). Like all plastic, however, 6-pack rings only degrade into smaller particles called micro plastics that are harmful when consumed by marine life that mistake them for food. For many consumers, 6-pack rings remain unpopular given the packaging’s checkered history.

Hi-Cone rings are made from #4 LDPE plastic, 50% of which is post-consumer recycled material (PCRM). They are not accepted in single-stream recycling programs but can be included wherever plastic film recycling is offered, such as municipal transfer stations and some supermarkets. Hi-Cone also offers a free, postage-paid mail-in recycling option called RingRecycleMe. As a result of the product’s light weight and minimal material design, it has the lowest carbon footprint of its competitors. It is also the least expensive option but requires capital investment in automated application machinery.

Craft-Pak carriers from Roberts PolyPro are made from virgin #2 HDPE plastic and can be applied by hand or with machine applicators. They are manufactured with 30% less material than industry leading competitor PakTech, and are therefore less expensive. Commonplace with almost all plastic packaging, the chasing arrows symbol is stamped on them so they can be marketed as fully recyclable despite common knowledge that they are not accepted in single-stream collection bins. Its durable material allows it to be reusable, but its likelihood of being reused is quite low.

Craft-Pak’s open-top design resembles the classic 6-pack ring, but its slightly narrower diameter exempts it from the EPA’s “degradable material” mandate. Despite the exemption, it still poses a significant entanglement risk for wildlife (just smaller wildlife) because of its dangerous design. Given the product’s durability, the risk of death to an animal that becomes entangled in them is even greater than the original 6-pack ring.

Made from 100% PCRM #2 HDPE plastic (beverage containers it purchases from materials recovery facilities or MRFs that service municipal recycling programs), PakTech is the dominant craft beverage packaging provider. Its 100% PCRM attribute, along with its “100% recyclable” claims, were major factors in its emergence as the packaging of choice for craft brewers when the canning trend took off.

As was later found out, PakTechs are recyclable in theory but not in the real world of a consumer and their single-stream recycling bin. Part of the problem is their shape. In the recycling industry they’re known as tanglers because they can wrap around the machinery and gum up the works. And because they’re flat, they often get missorted and end up contaminating paper and cardboard processing. Even if they escape those pitfalls, the popular black ones can’t be sorted by infrared scanners because black is undetectable to automated sorters. Ultimately, most end up going to the landfill or incinerator.

PakTech’s disingenuous recyclability claims have resulted in frequent criticism, but its colorful, convenient design has helped it retain dominance in the marketplace. Its easy and practical hand application and moderate price tag are also notable advantages. As accusations over greenwashing grew louder, PakTech launched a recycling program that amounted to little more than shipping a branded plastic collection bin to any brewery that requested one. Several hundred have taken them up on the offer, but PakTech supplies carriers to well over 7,000 beverage producers in the U.S. alone. And it’s up those businesses to arrange and pay for a plastics processor to haul their collected carries away for recycling. PakTech’s website lists only a few dozen such companies in 20 or so states that are currently doing so.

Ecogrip Rigid Plastic Can Carriers

For beverage producers in Australia, an alternative to PakTech is the near clone Ecogrip can carrier. Made from 100% Australian recycled plastic, and manufactured at a facility that draws half of its electricity from a solar farm, it shares most of the advantageous design and utility features as PakTech’s handles, and faces most of its recyclability challenges. One significant innovation worth noting is that its black can carriers use a carbon-free ink that makes them near-infrared transparent and therefore more likely to be properly sorted at Australian materials recovery facilities (MRFs).

PakTech (and maybe Ecogrip) Reuse

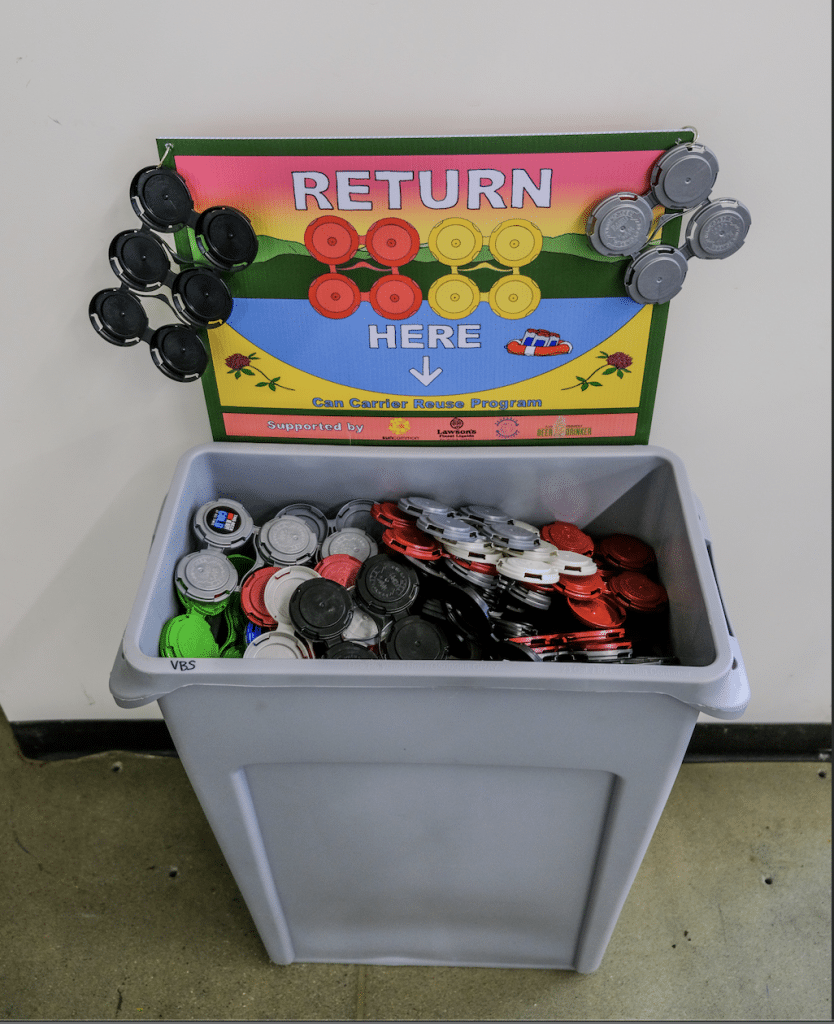

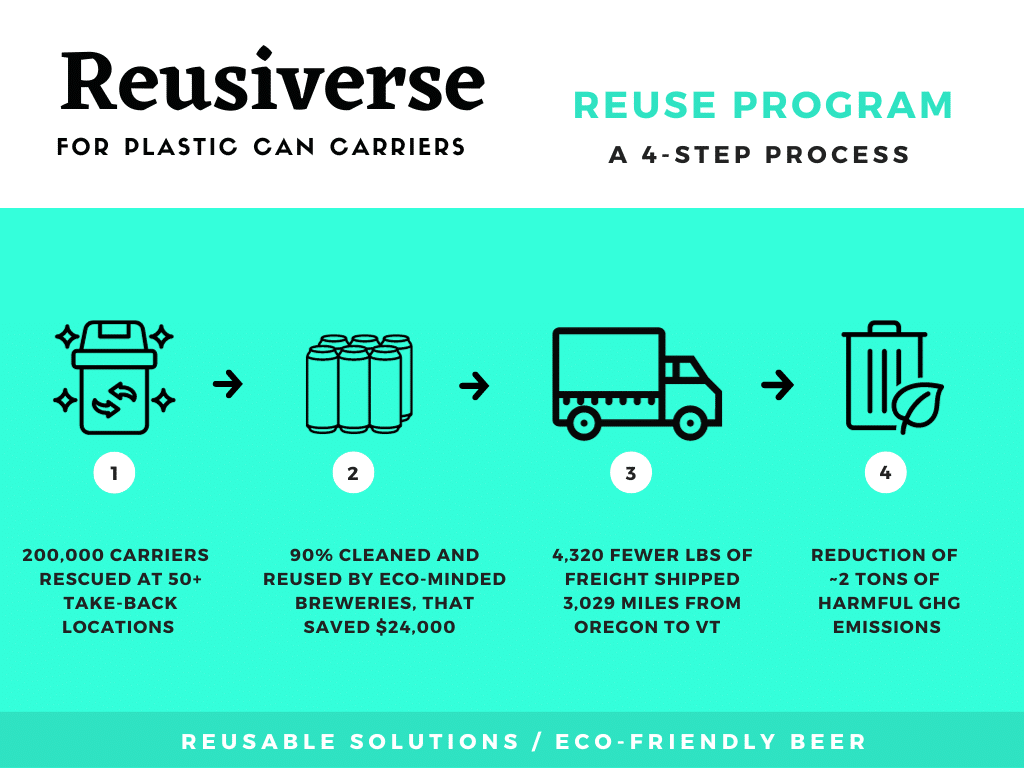

If a small brewery decides to go with plastic packaging (a decision likely to face increasing scrutiny), PakTech’s most redeeming quality is its durability and convenience regarding reuse. A successful consumer take-back program requires some thoughtful logistics but is typically popular with customers and can save a business money.

Untold Brewing in Massachusetts, Midwest Coast Brewing in Chicago, and Black Flannel Brewing in Vermont all boast successful take-back and reuse programs. Untold has a bin for take-backs in its taproom and partners with local retail accounts to accept their collected take-backs as well. At Midwest Coast consumers can earn a free pint for bringing in 25+ good-condition can carriers for the brewery to clean and reuse. Black Flannel has been so successful with its reuse efforts that it hasn’t needed to purchase new packaging in more than a year.

In Vermont, a multi-stake holder effort has succeeded in reducing the need for new PakTechs by allowing the ones already in circulation to be used over and over again. It’s difficult to calculate precisely, but reusing them prevents unnecessary energy required to manufacture new ones, decreases greenhouse gas emissions associated with additional deliveries, and spares wildlife harm from entanglement or micro plastic ingestion that can occur when plastic packaging isn’t properly disposed of.

Though not confirmed, Ecogrip can carriers appear to be similarly as durable as PakTech’s handles and could theoretically be just as viable in a reuse program. Brouhaha Brewery, Hop Nation, Tallboy & Moose, and Your Mates all use Ecogrip and might be able to lend some insight.

Corporate Social Responsibility

Regardless of business size, any beverage producer that’s packaging products in plastic should have a formal take-back program acknowledging that it’s NOT curbside recyclable and encouraging consumers to return their packaging to a brewery (including its own) for reuse or proper separate-stream recycling by a plastics processor. Likewise, proper disposal of compostable packaging should be communicated to consumers, and an on-site collection option provided if none exists in the municipality the business operates in. Funding for such a program should be built into any financial analysis regarding packaging decisions.

An alternative to plastic that has gained traction in the last few years is the Eco 6-Pack Ring or E6PR (also available in 4-pack format). First made popular by Florida’s Salt Water Brewery and now used by breweries worldwide, Eco Rings are made from plant fiber (agriculture by products) and are therefore biodegradable and compostable. Vastly improved since initial introduction, they typically hold up to retail and distribution demands (though performance can vary) and unlike their plastic counterparts are no threat to nature or wildlife if they end up in the environment.

Less pliable, they require a different application method than plastic snap-ons, which you can see in the video below. In a quest to eliminate plastic from its packaging, Whaler’s Brewing in Rhode Island recently partnered with E6PR to debut its first high-speed automated machinery for applying Eco Rings on six-packs of its flagship pale ale, Rise.

The ideal end-of-life destination for compostable products is a commercial composting facility (not a recycling bin), but if discarded on land or in water they will typically biodegrade over the course of several months. E6PR carriers had previously been more expensive than plastic competitors, but recently announced a significant price reduction bringing them in line with PakTech’s current cost. It’s worth mentioning that when costs associated with micro plastic pollution and its increasing human health concerns are considered, the real price of plastic becomes clearer.

Compostable World Centric Fiber Rings

A recent competitor, World Centric’s BPI certified compostable fiber can rings, are made from annually renewable plant fiber and its website states that they are PFAS free (a growing concern in the packaging industry). Their more appealing aesthetic and slightly cheaper price tag have started to catch the attention of beverage producers like Portico Brewing in Somerville, Massachusetts.

When working with plant fiber packaging, beverage producers should consider two utility quirks often associated with compostables: (1) the utility/integrity of the product can vary, resulting in cans occasionally coming loose, and (2) ironically, some consumers experience difficulty pulling cans from the rings because they are less pliable. To combat the second concern, Whalers Brewing used a social media post to educate its customers on proper technique for removing cans, “more twist, less pull.” Regarding the former, careful attention should be given to the application process and to retail distribution handling procedures.

WestRock’s Paperboard CanCollar

Developed by paper packaging giant WestRock, the CanCollar has become a popular alternative in the craft beverage industry because of its paperboard design. Made primarily from paperboard (of which, up to 15% comes from recycled material), it performs well in retail and distribution but is neither fully biodegradable nor easily recyclable. Its CarrierKote wet-strength material (plastic) is laminated to the paperboard to protect the carrier from moisture and rough handling, but such multi-layer material decreases its recyclability.

WestRock says the CanCollar is “recyclable (an average of 83% of the fiber will be recovered in a standard recycling process) wherever beverage cartons are accepted,” but according to the Carton Council only 61% of households in the U.S. currently have access to carton recycling. Breweries can use the trade group’s Carton Recycling Locator to check whether their state or municipality currently offer carton recycling. Cost is an advantage, but like its compostable counterparts, paperboard carriers require application machinery so that should be calculated into overall cost analysis.

Fishbone Paperboard Beverage Carriers

Competitor Fishbone recently debuted a new paperboard carrier design that contains no plastic whatsoever and is therefore 100% curbside recyclable. Though manufactured with renewable fiber from responsible sources, no recycled fiber is used. To ensure that its carriers don’t contribute to deforestation, a frequent focus of criticism by plastics manufacturers, Fishbone’s paperboard is sourced from Billerudkorsnas, considered the most sustainable packaging company in the world as quantified by the Dow Jones Sustainability Index.

Other paperboard packaging options continue to emerge, including the Eco-Cap-Clip and the WaveGrip, both made from recycled cardboard and marketed as 100% recyclable, as well as Earthrings, which promise to be recyclable, compostable, plastic-free and to hold up to moisture. Assuming each product’s claims are true (some verifications are pending), the application processes are manageable, and performance and cost are competitive, each could be another appealing option.

Packaging’s Carbon Footprint Is Complicated

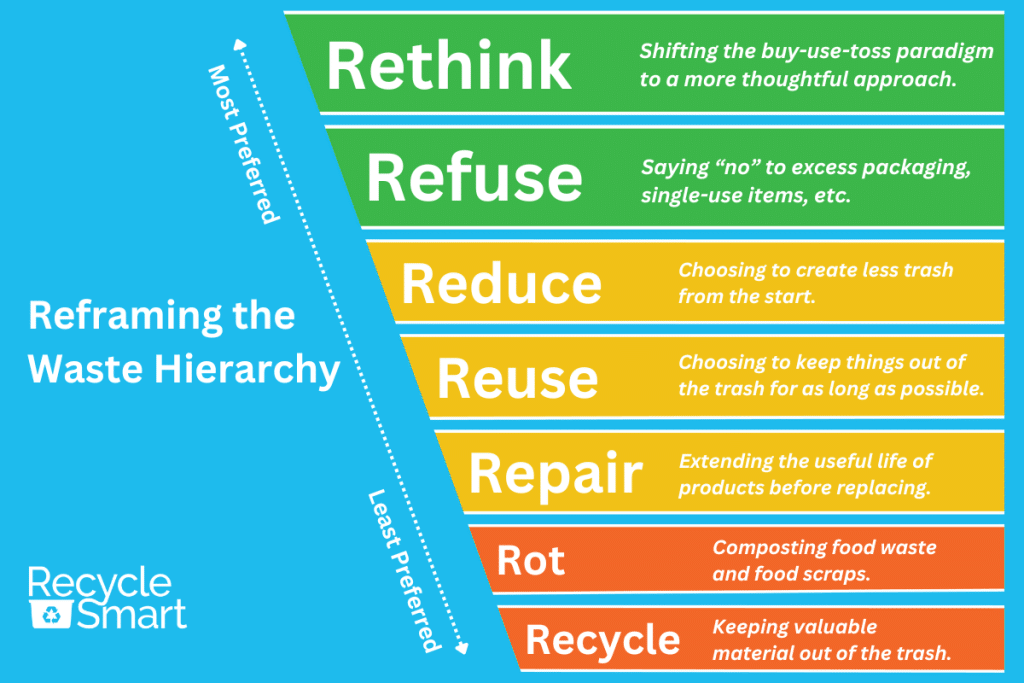

No comprehensive analysis regarding the carbon footprint of different can packaging options currently exists, but some reasonable assumptions can be made regarding their life cycles. The more material required to make the packaging, and the heavier the material is, the greater its carbon footprint is likely to be. Packaging made from recycled or repurposed material is generally less carbon intensive than packaging made with virgin material. Reused packaging will almost always have the lowest carbon impact of all, unless you forgo packaging all together – nothing beats that.

As one helpful study points out, “the plastic waste issue highlights the need to focus on reducing overall consumption rather than just material substitution. Interventions that lead to a true reduction of consumption will always decrease environmental impact.”

What About PFAS?

The short answer is we don’t know for sure which of these can carriers, if any, contain PFAS. But Consumer Reports recently tested more than 100 food packaging products from restaurant and grocery chains and found PFAS chemicals in many types of packaging, from paper bags for french fries and wrappers for hamburgers to molded fiber salad bowls and single-use paper plates. And earlier this year researchers added HDPE plastic to their list of packaging that have tested positive for such so-called forever chemicals. In fact, PFAS is used so widely—found in ink on food containers, recycled paper, machines that make packaging, and more—that it often shows up in products unintentionally.

Decisions, Decisions

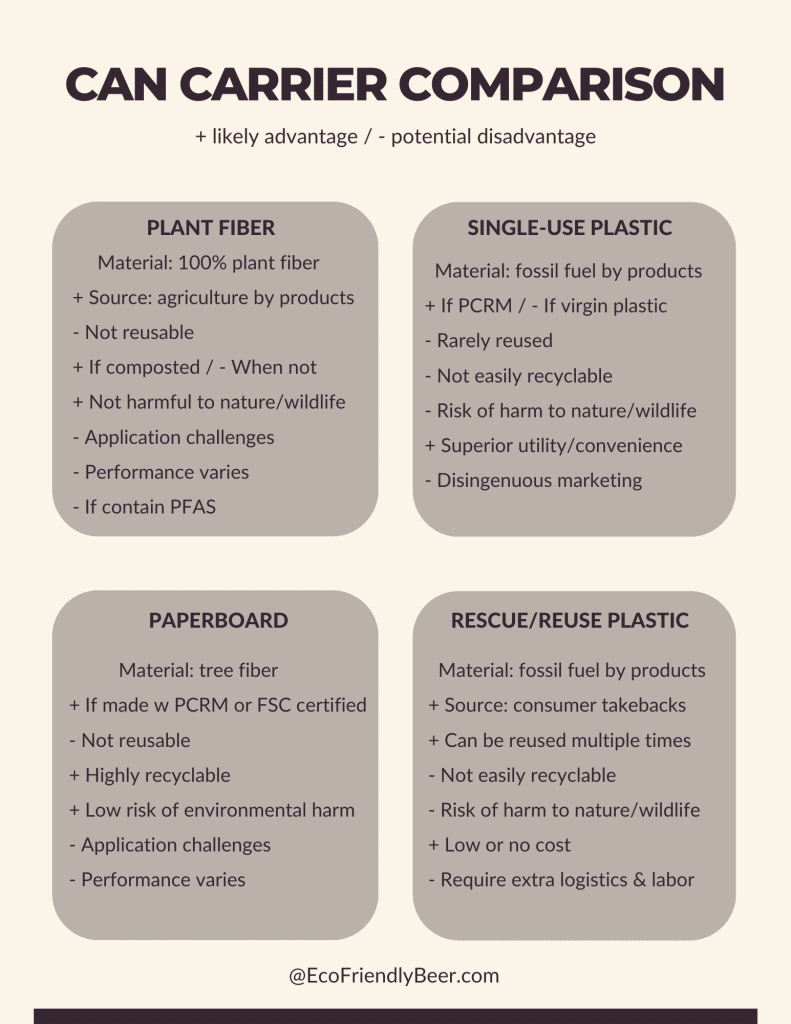

So which packaging choice is best from an environmental perspective? It’s clear that compostable plant fiber, recyclable paperboard, or reused plastic carriers are all better than single-use plastic. But the ultimate decision requires a full assessment of the various trade-offs when choosing one specific option over another. Depending on its location, business model, marketing approach, or company ethos, the choice may be different from one brewery to the next. The summary chart below provides some key pros and cons of each choice. If you would like to explore your brewery’s options in more detail, send an email to EcoFriendlyBeerDrinker@gmail.com.

Good summary, but I would have liked to hear about plastic labels on cans an how that effects the recyclability of the aluminum.

Hey Karl:

It would be ideal if all cans were labeled with ink only, which is not a contaminant. For practical reasons (economics, minimal available storage space, etc.), most small breweries (that’s about 75% of all breweries but only 25% of all craft beer production – big breweries produce most of the canned beer out in distribution) are using blank cans with stick-on or shrink-wrap labels. They will probably still get recycled if they reach a redemption center or recycling bin, for now. But as craft beer has grown, and more and more vinyl stick-on and shrink-wrap labels are being used, the aluminum recycling industry has started to become concerned about the level of contamination and other issues. Luckily, some breweries are starting to use tear-off labels so consumers will know to take them off before pitching cans into recycling bins. I’ve been told that in states like Colorado and Vermont, where craft beer is dominant, that cans are starting to be rejected. Here’s an excerpt from a good summary of the issue, written a few years ago by beer expert Kate Bernot: “They still take these cans for now, but the labels can cause issues with equipment wear-and-tear at recycling facilities. I’ve heard some facilities say that they can increase fire risk. Some say the labels reduce efficiency by introducing non-aluminum material into their processes,” he says. “And others say the plastic labels cause emissions spikes when the cans with them are melted down.” If you want to read the full story here’s the link: https://thetakeout.com/are-shrink-wrapped-beer-cans-recyclable-1832063063

Yes, your point about plastic labels on aluminum cans is crucial for a recyclability aspect. Plastic labels on aluminum cans indeed play a significant role in the overall recyclability equation. While aluminum itself is highly recyclable, the presence of plastic labels can pose challenges during the recycling process.

Ongoing efforts within the industry to adopt eco-friendly labeling practices and advancements in recycling technologies are essential for maximizing the environmental benefits of aluminum can packaging.

Hey Kerrin:

The unfortunate reality is that single-use packaging, regardless of the material it’s made from, isn’t actually sustainable. Hence the waste hierarchy: REDUCE, Reuse, recycle (which is abysmal in the U.S.). Nothing beats drinking a draught beer in proper reusable glassware at the brewery’s taproom.